JurbySoft 67 biocide performance of controlling coliforms in cooling system water

- Sep 14, 2023

- 2 min read

Updated: Sep 20, 2023

Industry | Oil Refining and Petrochemical |

|---|---|

Type | Open cooling system water treatment |

Task | The problem is significant amounts of sodium hypochlorite whic is required for biological control of bringing total coliform bacteria (threshold than 20 CFU/100 ml) and thermotolerant coliform bacteria (10 CFU/100 ml) up to the standard values in the recycled system water during the summertime. Need to offer an alternative biocide that would be more effective and less corrosive to system components |

Water source | River water |

About project

The cooling system is located in the unit of oil refinery where the isomerization of pentane-hexane fractions occurs. The cooling system water in the compartment is used to cool down this equipment.

Water treatment programme

Currently, the cooling tower water is treated with multifunctional corrosion and scale inhibitor, oxidising and two non-oxidising biocides as well as biodispersant to enhance biocidal treatment and dispersant that improves residues dispersion.

Results

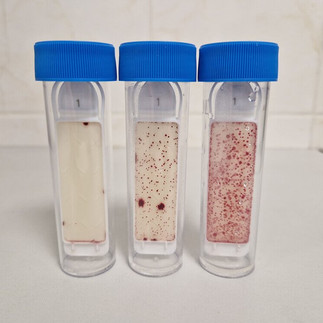

Following an analysis of the object data, it was proposed that JurbySoft 67 microbicide to be tested in the factory. A pilot experiment was carried out and JurbySoft 67 biocide was used instead of sodium hypochlorite.

Main technical parameters of the cooling system

Parameter | Units | Values |

|---|---|---|

System volume | m3 | 700 |

Recirculation | m3/h | 1300 |

Temperature difference | °С | 9 |

Cycles of concentration | - | 2.5 |

Evaporation | m3/h | 10 – 15,6 |

Makeup | m3/h | 27 winter / 33 summer |

Losses + drift | m3/h | 10.4 |

The results of the in-plant experiment

The pilot experiment with the biocide JurbySoft 67 in the plant lasted 10 weeks. During this period, different doses of the product were tested in the cooling system water. The results of the in-plant experiment are shown in the table below. In addition, total bacterial counts, sulphate reducing bacteria and Legionella Pneumophila were also measured during the experiment

Week | Biocide dose, g/m3 | Total coliform bacteria (<20 CFU/100 ml) | Thermotolerant coliform bacteria (<10 CFU/100 ml) | Coliphage (<10 CFU/100) |

|---|---|---|---|---|

1 | 70 | undetectable | undetectable | undetectable |

2 | 70 | undetectable | undetectable | undetectable |

3 | 50 | 1200 | 1200 | undetectable |

4 | 70 | undetectable | undetectable | - |

5 | 60 | 680 Oil leakages | 680 Oil leakages | undetectable |

6 | 70 | <1.9 Oil leakages | <1.9 Oil leakages | <1 |

7 | 70 | undetectable | undetectable | - |

8 | 60 | 7200 | 7200 | - |

9 | 70 | undetectable | undetectable | - |

10 | 80 | undetectable | undetectable | - |

Summarize

1. The results of pilot tests show that the most effective dose of JurbySoft 67 for the treatment of oil refinery cooling water in summer is 80 g/m3 twice a week. This dose ensures the achievement of results during the summer period at high ambient temperatures, in the presence of oil products and unstable water quality.

2. The analysis of the results shows that the application of JurbySoft® 67 to achieve microbiological safety is positive. Total coliforms and thermotolerant coliforms were below the required limit.

3. During the test period, the microbial contamination of the circulating water was no more than 104 CFU/ml for total bacteria and no more than 103 CFU/ml for sulphate-reducing bacteria. The amount of Legionella Pneumophila in recycled water did not exceed 20 CFU/l (100 CFU/l limit).

4. Finally, the corrosion rate during the test period was within the normal limits (threshold not higher than 0.1 mm/year): 0.0634 mm/year and 0.0452 mm/year.

Comments